We just got back from PACK EXPO Chicago 2024, and wow—what an event! From record-breaking attendance to some of the coolest booth experiences we’ve ever seen, this year’s show was one for the books. Whether you’re an OEM, a Power Transmission Distributor, or a Plant Operations Manager, here’s a look at what stood out and why it matters to you.

PACK EXPO Chicago 2024 Highlights That Matter to You

Dec 2, 2024 4:50:39 PM / by Slideways, Inc. posted in conveyor components, conveyor systems, News

Why Conveyor Manufacturers Choose Slideways for Custom Plastic Machined Parts

Apr 10, 2024 4:18:43 PM / by Slideways, Inc. posted in conveyor systems

Keep Your Conveyor Parts Running Smoothly with Slideways

Mar 29, 2024 8:48:24 AM / by Slideways, Inc. posted in conveyor components, conveyor systems

5 Reasons Slideways Works for OEMs with In-House Machining

Mar 4, 2024 11:16:00 AM / by Slideways, Inc. posted in industry, machined, conveyor systems, plastic supplier, custom plastic fabrication, News

Slideways is a valuable partner even for those OEMs with in-house machining capabilities.

Many of our customers have extensive machine shops. So why is Slideways machining their plastic parts? It’s a few things that add up to a better solution for our customers.

Unpacking Pack-Expo: 4 Observations and a Bonus!

Oct 3, 2023 11:12:16 AM / by Slideways, Inc. posted in insider, industry, conveyor systems, News

1. Planned Maintenance Program

We asked several customers if they had a planned maintenance program, and the main response was…

• Yes, but If it's not broken, we don’t shut our lines down to fix it• Yes, but we aren’t as proactive as we should be

• Yes, but we fix some things but not others

Unpacking Tom's 4 Takeaways (+ 1 Bonus Takeaway) from PackExpo

Nov 8, 2022 12:39:45 PM / by Slideways, Inc. posted in insider, industry, conveyor systems, News

PackExpo International 2022 was a great success for Slideways and the Packaging Machinery industry. With masks and social distancing behind us, it was so nice to share a smile and a handshake with visitors to the Slideways booth. Component suppliers and machinery OEMs pulled out all the stops with extensive booths showing their products and machines loaded with the latest technology.

Here are 4 observations from the show.

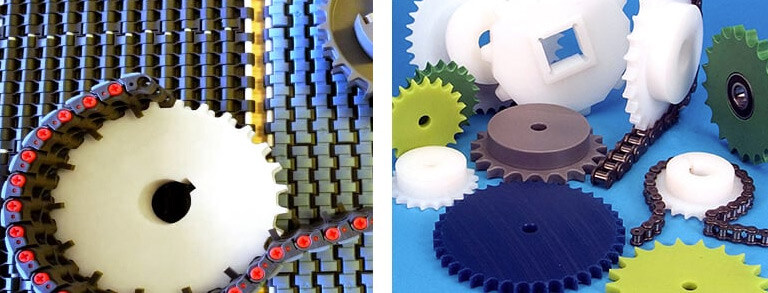

Types of Sprockets and Plastics Used in the Food Industry

Mar 11, 2022 12:27:19 PM / by Slideways, Inc. posted in materials, fda compliant, conveyor systems, food transportation, plastic sprockets

Plastic sprockets are a fundamental part of any food conveyor system or food processing machinery. Plastics have long been identified as some of the safest and most efficient materials for use in the food handling industry. Plastic properties such as wear resistance, wide operating temperature ranges, and superior tensile strength offer many benefits. Plastic sprockets are lightweight, durable, and easy to clean, which provides food handling equipment manufacturers with a reliable and versatile component for use in a variety of food preparation and transportation systems.

Tight Tolerance Ranges for Machined Plastic Parts Aren’t Always Needed

Dec 21, 2021 2:10:24 PM / by Slideways, Inc. posted in conveyor components, machined, conveyor systems

Slideways manufactures precision plastic parts for conveyors and packaging machinery. This market encompasses a variety of unique applications that require different part tolerancing considerations. Factors affecting part tolerance include application, part size, and material. This blog will explain the typical applications and materials Slideways works with when designing conveyor and packaging machinery components.

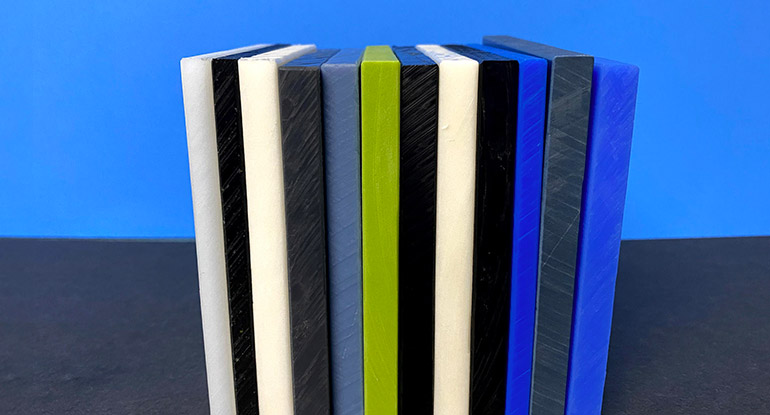

Which UHMW Properties Are Best for You?

Jul 23, 2021 10:12:10 AM / by Slideways, Inc. posted in uhmw, conveyor systems, high-temp, temperature stable, heat resistant, impact strength

UHMW (ultra high molecular weight polyethylene) plastic is the choice material for conveyors and packaging machinery. Its unique properties, ease of fabrication, and low-cost make it the optimal selection for this industry. Its ability to handle abrasion, impact, corrosive cleaning solutions, and wet environments enables UHMW to stand up to extensive wear and tear. Additionally, its dampening properties reduce conveyor noise and vibration. Made in large sheets for big or long parts, UHMW machines easily and can be extruded into complex profiles with thick or thin cross-sections. All these attributes make UHMW a great option for machine builders and maintenance personnel that are concerned with price, extending the life of initial installations, and repairs.

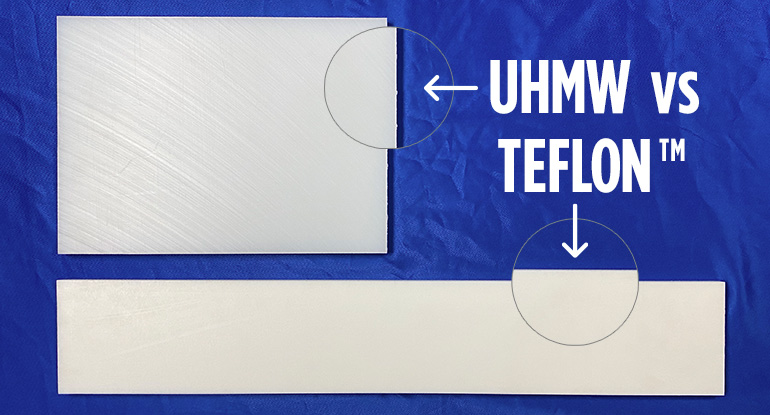

UHMW vs Teflon™ in Packaging Machinery and Conveyor Applications

Apr 2, 2021 1:39:57 PM / by Slideways, Inc. posted in uhmw, conveyor systems, high-temp, temperature stable, heat resistant, impact strength

Slippery Plastic Smackdown!

Slideways frequently fields quote requests for parts made of Teflon™, the brand name for PTFE (Polytetrafluoroethylene). Once learning more about the application, we usually determine a UHMW (ultra-high molecular weight polyethylene) part is needed. Teflon has a place in packaging machinery, but it is not the go-to material until some specific operating conditions are met.