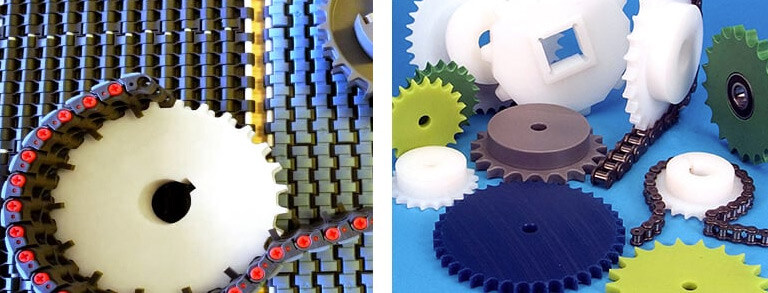

Plastic sprockets are a fundamental part of any food conveyor system or food processing machinery. Plastics have long been identified as some of the safest and most efficient materials for use in the food handling industry. Plastic properties such as wear resistance, wide operating temperature ranges, and superior tensile strength offer many benefits. Plastic sprockets are lightweight, durable, and easy to clean, which provides food handling equipment manufacturers with a reliable and versatile component for use in a variety of food preparation and transportation systems.

Types of Sprockets and Plastics Used in the Food Industry

Mar 11, 2022 12:27:19 PM / by Slideways, Inc. posted in materials, fda compliant, conveyor systems, food transportation, plastic sprockets

How to Increase Productivity in Manufacturing Company with Plastic

Oct 21, 2016 9:41:00 AM / by Slideways, Inc. posted in plastic, fda compliant, conveyor systems

Every manufacturer focuses on improving productivity. That's why figuring out how to increase productivity in manufacturing company has brought about lean manufacturing strategies which continue to gain popularity.

Companies are constantly looking to minimize downtime, maximize operational efficiencies, and reduce costs to efficiently improve manufacturing. What some manufacturers fail to understand, though, is that productivity can only be as good as your equipment.

Conveyor Components for Ultra-High Manufacturing Performance

Dec 17, 2014 10:13:00 AM / by Slideways, Inc. posted in conveyor components, plastic, fda compliant, uhmw, blulub, x-ray

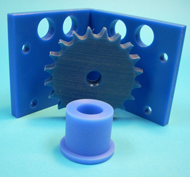

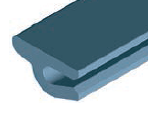

Demanding manufacturing processes faced with extreme environmental or stringent liability challenges need conveyor systems that can meet lofty standards of performance and reliability.

If you’re a discrete or process manufacturer operating in a tough production environment, high-performance plastic conveyor components can upgrade your conveyor systems to top efficiency.