Lean manufacturing. It’s the buzzword echoing across shop floors everywhere. And for good reason—cutting waste, boosting efficiency, and keeping production moving is what separates thriving operations from those constantly playing catch-up. But here’s something you might not realize: your conveyor system plays a massive role in this lean revolution.

Slideways, Inc.

Recent Posts

How Plastic Conveyor Parts Contribute to Lean Manufacturing Principles

Feb 19, 2025 12:44:55 PM / by Slideways, Inc.

Optimizing Industrial Conveyor Systems Performance with Advanced Plastic Parts

Dec 5, 2024 3:11:58 PM / by Slideways, Inc.

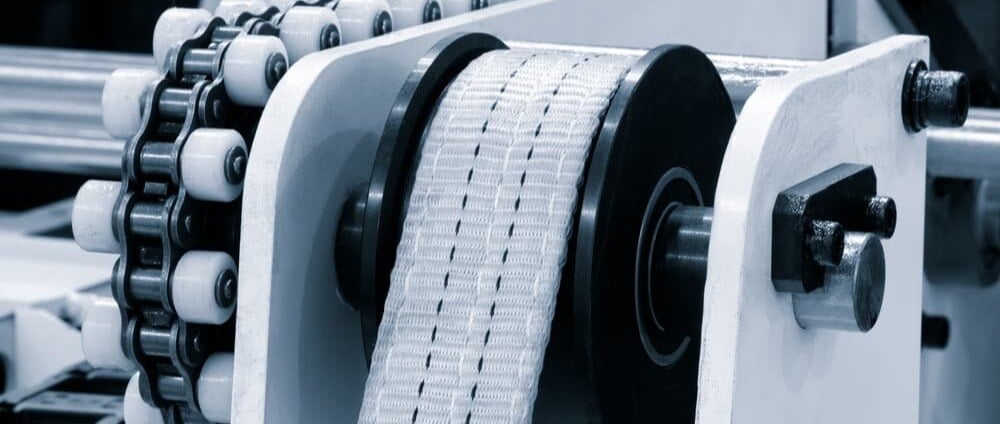

Industrial conveyor systems are essential in many industries for streamlining operations, especially in material handling equipment. These systems are vital for transferring goods across production lines and assembly lines in manufacturing and production facilities.

PACK EXPO Chicago 2024 Highlights That Matter to You

Dec 2, 2024 4:50:39 PM / by Slideways, Inc. posted in conveyor components, conveyor systems, News

We just got back from PACK EXPO Chicago 2024, and wow—what an event! From record-breaking attendance to some of the coolest booth experiences we’ve ever seen, this year’s show was one for the books. Whether you’re an OEM, a Power Transmission Distributor, or a Plant Operations Manager, here’s a look at what stood out and why it matters to you.

Comparing Plastic vs. Metal Conveyor Parts: Which is Right for Your Application?

Oct 18, 2024 5:04:37 PM / by Slideways, Inc.

When it comes to choosing conveyor parts for your system, the decision between plastic and metal components is crucial. Each material offers distinct benefits and limitations, and understanding these differences can help you select the best option for your specific needs.

How Plastic Conveyor Parts Improve Workplace Safety and Efficiency

Oct 2, 2024 10:51:16 AM / by Slideways, Inc.

One of the most effective strategies for improving productivity is incorporating plastic parts into conveyor systems. Unlike their metal counterparts, plastic conveyor parts offer distinct advantages that make work environments safer and contribute to better ergonomics.

Save Big with Plastic Conveyor Parts: The Ultimate Guide

Aug 26, 2024 5:20:45 PM / by Slideways, Inc.

Choosing the right parts for your conveyor system can mean the difference between a smooth-running operation or constant headaches. One of the best ways to enhance your conveyor system? Plastic conveyor parts. Not only are they cost-effective, but they also provide numerous benefits that can positively impact your bottom line.

Tips for Maintaining and Extending the Lifespan of Plastic Conveyor Parts

Aug 2, 2024 5:26:53 PM / by Slideways, Inc.

Plastic conveyor parts are critical in various industrial applications, ensuring efficient and smooth material handling processes. These components, while durable, require proper maintenance to maximize their lifespan and performance.

How Plastic Conveyor Parts Enhance Manufacturing Efficiency Operations

Jun 11, 2024 3:50:31 PM / by Slideways, Inc.

With the increased demand for products in today's marketplace, manufacturers, distribution centers, and warehouses are working tirelessly to keep up. A big part of their success hinges on having the right conveyor systems tailored to their needs.

The Importance of Choosing a Reliable Plastic Conveyor Parts Manufacturer

Jun 11, 2024 3:46:21 PM / by Slideways, Inc.

In many industrial settings, where movement, efficiency, and productivity are important, the reliability of conveyor systems stands as a linchpin. Central to this reliability are plastic conveyor parts that keep operations flowing smoothly. Yet, the manufacturer of these parts is often overlooked, leading to repercussions that ripple through production lines.

Why Conveyor Manufacturers Choose Slideways for Custom Plastic Machined Parts

Apr 10, 2024 4:18:43 PM / by Slideways, Inc. posted in conveyor systems

.png)

.png)