Slippery Plastic Smackdown!

Slideways frequently fields quote requests for parts made of Teflon™, the brand name for PTFE (Polytetrafluoroethylene). Once learning more about the application, we usually determine a UHMW (ultra-high molecular weight polyethylene) part is needed. Teflon has a place in packaging machinery, but it is not the go-to material until some specific operating conditions are met.

Teflon and UHMW are both slick, often white plastics. Both are approved for direct food contact and don’t absorb water. Teflon and UHMW also have excellent resistance to the cleaning solutions and lubricants found in most conveyor and packaging machinery applications. This is where the similarities end.

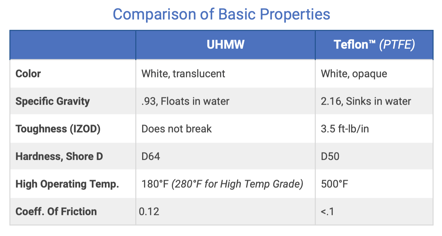

For conveyor and packaging machinery applications, we are most concerned with mechanical properties. UHMW has superior mechanical properties for wear, compressive strength, and impact resistance. Teflon is comparably soft and will creep due to its chemical structure. This results in rapid abrasion in dusty or gritty environments. Because Teflon is a softer material, you can tell the difference between Teflon and UHMW by pressing your thumbnail into the material. Your thumbnail will indent Teflon much more easily than it will UHMW or other mechanical grade plastics.

Another difference is cost. Teflon is 10X the price of UHMW because of the high temperature (621oF) required for creating the strong chemical bonds that produce Teflon. These strong chemical bonds are the source of Teflon’s temperature resistance and inert properties that make it exceptionally resistant to chemical attack. The strong chemical bond also prevents cross-linking of molecules, and that prevents Teflon from having better mechanical properties.

The poor wear properties and expense mean the only time to use Teflon is when you absolutely require the high operating temperature capability of 500oF or the improved chemical resistance over UHMW.

Standard UHMW grades have a high operating temperature of 180oF, and High-Temp UHMW has a high limit of 280oF.

Perfect Applications for Each

UHMW is used in conveyor systems and packaging machinery applications that are running at temperatures below 180oF. These will include chain guides, belt guides, guide rails, bumpers, bushings, and bearings. Really anything that slides or has something sliding against it are appropriate applications for UHMW.

UHMW is used in conveyor systems and packaging machinery applications that are running at temperatures below 180oF. These will include chain guides, belt guides, guide rails, bumpers, bushings, and bearings. Really anything that slides or has something sliding against it are appropriate applications for UHMW.

Teflon applications on conveyor systems are less common since conveyors tend to operate at less extreme temperatures. We are more likely to see Teflon on packaging machinery like shrink tunnels and ovens where heat is higher than UHMW can handle. Slideways has made Teflon parts for use near heating elements on labeling equipment and in lab equipment dealing with corrosive chemicals.

Improving the Properties of Each

Both Teflon and UHMW are made in formulations that enhance their properties. UHMW formulations include static reduction, lower friction, higher compressive strength, increased hardness, and temperature resistance to 280oF.

Since Teflon’s weaknesses are wear and compressive strength, additives like glass beads or fibers, and graphite improve both of those characteristics helping it to last longer in belt support applications.

Conclusion

You will get the best ROI and minimize down-time by selecting the right material for the job. Look at your application speed, load, operating temperature, chemical exposure, and exposure to dirt and grit. Plan on utilizing UHMW until conditions exceed the 280oF limit of high-temp UHMW. Over time, this will save you money by producing a longer lasting part.