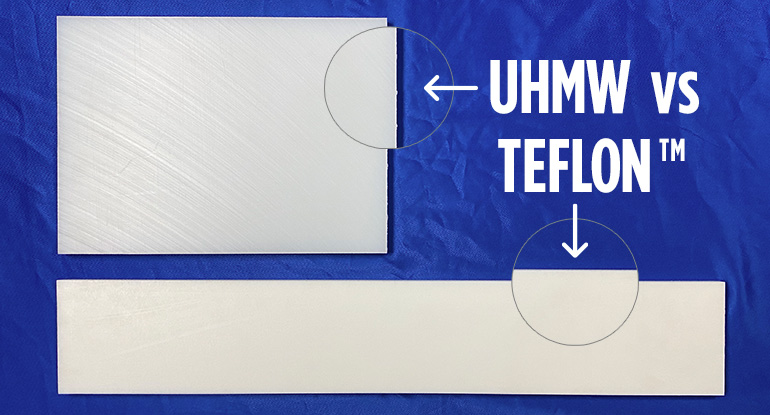

Slippery Plastic Smackdown!

Slideways frequently fields quote requests for parts made of Teflon™, the brand name for PTFE (Polytetrafluoroethylene). Once learning more about the application, we usually determine a UHMW (ultra-high molecular weight polyethylene) part is needed. Teflon has a place in packaging machinery, but it is not the go-to material until some specific operating conditions are met.

How “custom” is a custom roller? At Slideways, the short answer is “as custom as you need it.”

How “custom” is a custom roller? At Slideways, the short answer is “as custom as you need it.” Slider beds are like roller beds; they help you transport and accumulate products.

Slider beds are like roller beds; they help you transport and accumulate products.

Virtually every manufacturing and distribution operation uses conveyor systems to move parts and finished products from one location to another and from one process to the next.

Virtually every manufacturing and distribution operation uses conveyor systems to move parts and finished products from one location to another and from one process to the next.

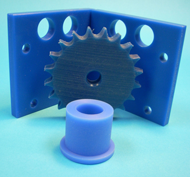

It’s not hard to understand why some product designers and engineers would hesitate to use plastic bearings in their designs.

It’s not hard to understand why some product designers and engineers would hesitate to use plastic bearings in their designs.